Designing

an instrument from a clean sheet of paper allows the opportunity

to re-examine certain

elements of that design. In this section you will find information

about those kinds of advancements in shop tooling and guitar construction

used here in the Eichelbaum shop every day. You will not only

see photos of construction methods, but also in-depth descriptions

of design concepts and techniques. Please check back often, as

this section will be updated frequently.

Designing

an instrument from a clean sheet of paper allows the opportunity

to re-examine certain

elements of that design. In this section you will find information

about those kinds of advancements in shop tooling and guitar construction

used here in the Eichelbaum shop every day. You will not only

see photos of construction methods, but also in-depth descriptions

of design concepts and techniques. Please check back often, as

this section will be updated frequently.

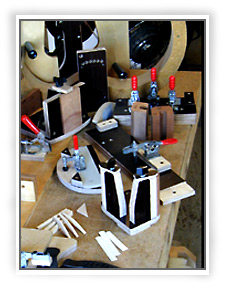

The

Bolt-on Neck Joint

Traditional

dovetail neck joints are more than adequate when properly executed.

However, I find that employing a full 3/4" slip-fit mortise

and tenon joint offers significant advantages. First, this method

enhances the sound quality of the guitar. Because I use two mechanical

fasteners to pull the heel snugly into the neckblock and guitar

sides, more direct contact in this area relates to a greater integrity

of sound transmission from the neck to the body. Second, this

method improves the accuracy of manufacture. Neck angles can be

precisely set without disturbing the strength of the joint, since

no glue surfaces are affected by changes. Third, this method promotes

ease of removal. Should the neck require removal, all that is

needed is to remove the fasteners and lift the fingerboard from

the soundboard in the traditional way. This can be accomplished

in less than fifteen minutes with no worry of damage from "steaming"

the joint apart.

Traditional

dovetail neck joints are more than adequate when properly executed.

However, I find that employing a full 3/4" slip-fit mortise

and tenon joint offers significant advantages. First, this method

enhances the sound quality of the guitar. Because I use two mechanical

fasteners to pull the heel snugly into the neckblock and guitar

sides, more direct contact in this area relates to a greater integrity

of sound transmission from the neck to the body. Second, this

method improves the accuracy of manufacture. Neck angles can be

precisely set without disturbing the strength of the joint, since

no glue surfaces are affected by changes. Third, this method promotes

ease of removal. Should the neck require removal, all that is

needed is to remove the fasteners and lift the fingerboard from

the soundboard in the traditional way. This can be accomplished

in less than fifteen minutes with no worry of damage from "steaming"

the joint apart.

![]()

![]()

![]()

![]()